Today is already tomorrow

Thanks to several certifications and an experienced and passionate team, Sicit offers high quality standards, a fast and punctual delivery service, customization of products, a well-stocked and always available warehouse.

According to the famous principle “The whole is greater than the sum of its parts”, we are certain of the need to provide not only a product – which must always be of the highest quality and able to guarantee the required performance – but the whole: from design, to manufacturing, to customer service and any other aspect that can reduce overall costs and hence prices.

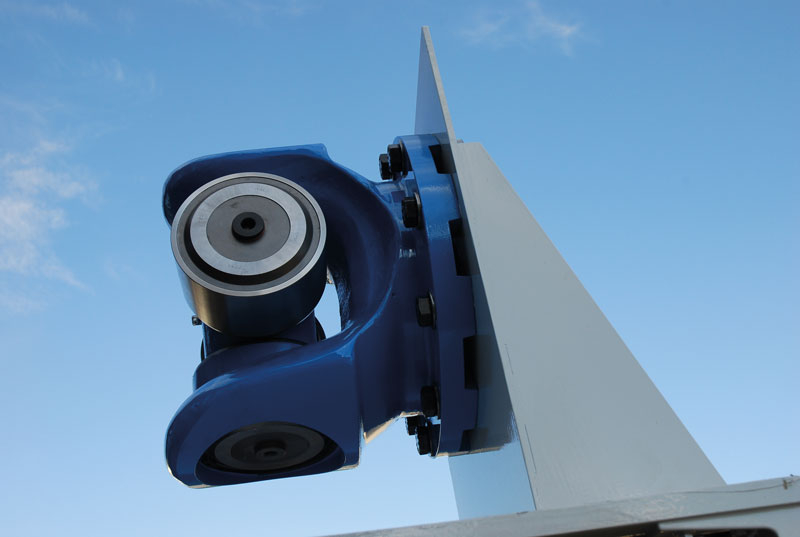

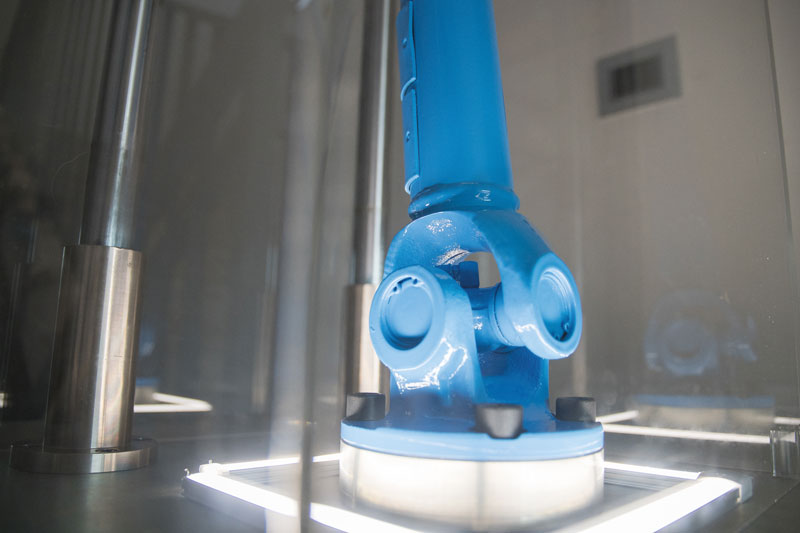

For this reason we decided to set up the CARDANWORKS division with a team of highly experienced professionals with specific skills in engineering, production and customer service for all the components that make up the cardan transmission.

We offer a range of optimal solutions and products, including flanges from 75 to over 840 mm diameter and torque capacity up to over 3,000 kNm.

The CARDANWORKS range includes a variety of products ranging from transmissions for commercial vehicles, industrial vehicles and heavy industry, both in terms of components and complete shafts.

HISTORY AND TRADITION

Sicit began its artisan activity in 1953, as a workshop for the production of universal joint crosses. It was a great moment for the Italian mechanical industry and the company soon distinguished itself for its precision in workmanship and punctuality with customers, two assets which are still two pillars of the company today.

In 1975 Sicit passed from being a workshop to a modern company through significant investments.

Those were the years when technology was becoming an integral part of our life and Sicit understood its importance right from the start.

In the 1980s and ‘90s the first CNC machines with their automation were introduced, both in the turning and grinding processes. As a result, the processes and their layouts could be better defined.

At the beginning of the 2000s, robotized production was implemented and the production cycles were further adapted and improved, in particular as regards process control.

As a result, the repetitiveness and continuity of quality became even more guaranteed.

Later on, a fully computerized manufacturing process management was also introduced, in order to control all production parameters in real time, thus guaranteeing complete traceability.